THE MANIFOLD STUDS

| > Hi Meli... > I have started on a Model B restoration and I am faced with whether to try and replace the very rusted manifold bolts. | ||

|

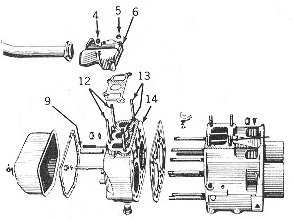

Taking off and restoring the manifold is a VERY difficult job, NOT to be taken lightly! First of all, those are NOT bolts - they are STUDS (parts 12 & 13) with nuts (parts 4 & 5) on top, or they properly SHOULD be studs, unless someone has already mistakenly replaced them with bolts. | ||

| | ||

|

| |

| > The top of the bolts are rusted away to a point with no thread showing. Do they generally come out okay ? |

| The nuts will Probably NOT come off, and the studs have deteriorated to the point that they need to be replaced ANYWAY! They do NOT come out okay.... Do NOT try to turn them; they will twist off!! Repeat... They WILL twist off!! |

| > Is there a trick to it other than just lubricating ? |

| If you don't have access to an acetylene torch, don't even ATTEMPT this job!! You need to take the entire head off the engine... manifold and all. Then you need to heat up each corner of the head red hot! I MEAN IT - RED HOT!! Then you should be able to unscrew the studs with vise grips or a stud gripping tool. |

| > if I cut them off and remove the manifold will I be sorry. |

| Just cut the nuts off at the top so you can remove the manifold. Do NOT pry the lower EARS of the manifold!! They WILL break off!! When the manifold is off, you will be able to grip the studs at the bottoms of them, when you remove them. You'll NEVER get the threaded holes in the head properly cleaned out if you break the studs off in them. BELIEVE me, the torch is the ONLY way to go! This method was taught to me by an expert, and I have done it, and it WORKS!! Then you need to get NEW studs. Do NOT use bolts! The studs will have a tight thread at the bottom. This is necessary because the holes go all the way into the water jacket and coolant will leak if you use ordinary bolts. Even WITH the proper studs, you should use a water-tight sealer when you install them. ANOTHER thing to watch out for is, be careful not to damage the brass pushrod sleeves (part 9, four of them) when you are cleaning the holes in the head. You will end up taking everything apart AGAIN when you find water in your crankcase. Then, of course, you must install the manifold back onto the head BEFORE you reinstall the head onto the block -- unless you have taken everything else off of the upper structure of the tractor. In that case, you might get away without removing the head at all. But I still recommend it. It probably needs a valve job anyway. |

Go back to the page you just came from......